-

Aluminum Extrusion products

- Furniture Aluminium Profile

- other industrial application

- heat insulation aluminium profile

- aluminium louver

- cabinet aluminium profile

- aluminium ladder profile

- aluminium curtain wall

- handrail aluminium profile

- aluminium furniture profile

- aluminium angle

- aluminium floor tile

- aluminium square tube

- aluminium round tube

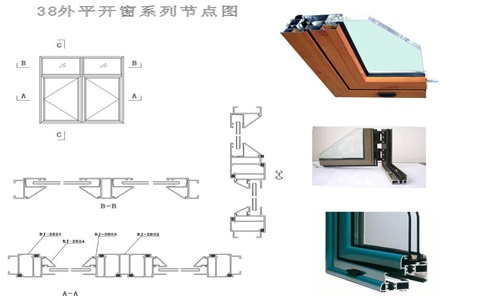

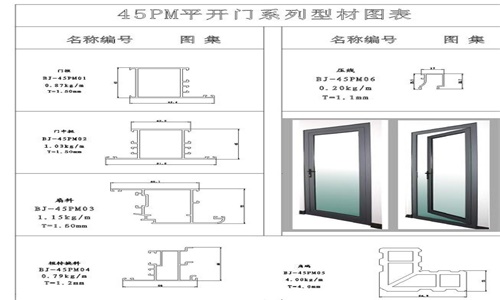

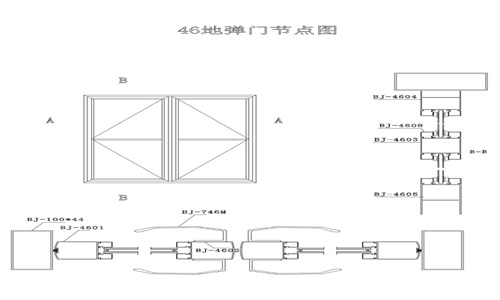

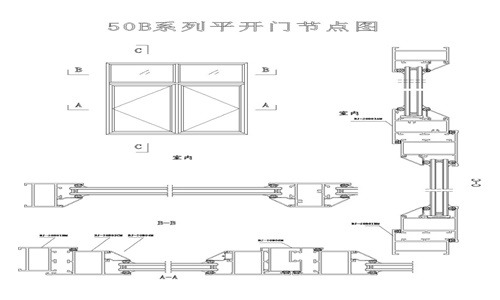

- aluminium window door

-

aluminium profile

- Veined brush aluminium profile

- Fluorocarbon coating aluminium profile

- Mechanical polishing aluminium profile

- Chemical polishing aluminium profile

- Sandblasting aluminium profile

- Woodgrain like aluminium profile

- Electrophoresis coating aluminium profile

- Powder coating aluminium profile

- Anodized aluminium profile

- Mill finish aluminium profile

- aluminium frame solar energy panel

- Aluminum die-casting products

- Steel fabrication products

- Plastic injection products

- Plastic blowing products

- Electromechanical(Metal &plastic&electric composites)

01

Plastic Blowing Products

product display

product description

- Hollow blow molding, a rapid process of plastic processing. During the Second World War, the blow molding began to be used to produce low density polyethylene flask. In the late 50s, with the birth of high density polyethylene and the development of blow molding machine, blow molding technology has been widely used.The volume of the hollow container can reach thousands of liters, and some of the production has been controlled by computer.

- The plastics for blow molding are polyethylene, polyvinyl chloride, polypropylene, polyester and so on. The hollow containers are widely used as industrial packaging containers. The blow molding can be divided into extrusion blow molding and injection blow molding, and the newly developed multi layer blow molding and tensile blow molding are newly developed.

- Extrusion blow molding is a method of making hollow thermoplastic parts. The widely known blow molding objects include bottles, barrels, cans, boxes, and containers for all packaged foods, beverages, cosmetics, medicines and daily necessities. Large blow molding containers are usually used in the packaging of chemical products, lubricants and bulk materials. Other blowing products include balls, bellows and toys. For the automotive industry, the fuel tank, the sedan shock absorber, the seat backrest, the center bracket, and the armrest and the headrest cover are blown. For machinery and furniture manufacturing, blow molding parts a shell, frame, door frame, pots or to have an open the box.